TPT Launches New Red Range Shafts With Automatic Improvement Guarantee

- Details

- Category: Inside Golf

- Published: 2020-04-18

With its new Red Range shafts for drivers, TPT is removing any doubt that its automated manufacturing technology will take golfers further.

The Red Range introduces the Automatic Improvement Guarantee, a statement of the confidence from the company that its Red Range shafts will offer golfers longer drives, straighter drives, and more confidence when fit by a TPT Authorized Fitter.

“In the golf industry the priority is not being put on the shaft; it’s being put on the head,” says TPT Co-Founder Francois Mordasini. “Our competitors are using a 30-year-old process that places limits on performance and consistency. What we’ve done is develop an entirely new, automated shaft manufacturing process that offers golfers a new level of performance and consistency. They will feel it immediately.”

The Automatic Improvement Guarantee is simple. If golfers aren’t seeing the same improved performance with a TPT shaft that they saw in their fitting, they can return it to their participating TPT Authorized fitter within 30 days of purchase for a return or exchange.

The Red Range

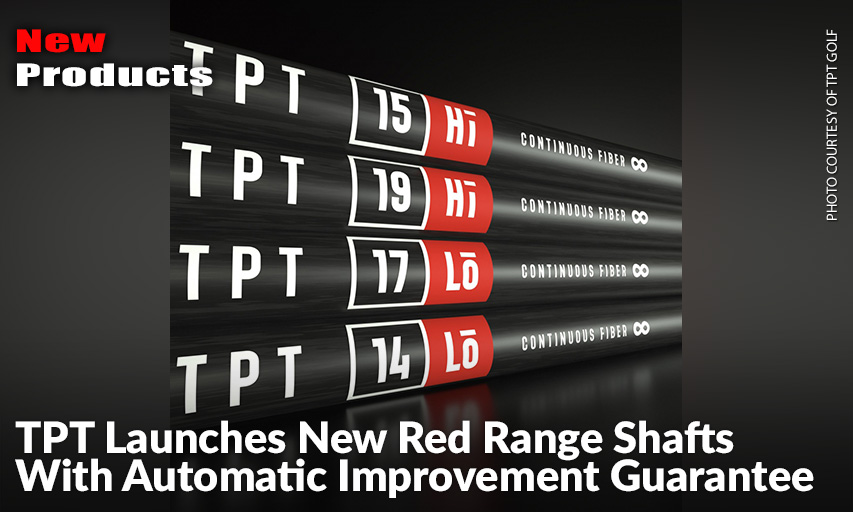

Red Range shafts ($500) are available in 12 models that will meet the needs of the vast majority of golfers — from the strongest golfers in the world to juniors and seniors.

TPT developed the Red Range with the feedback of PGA Tour winners and leading club fitters around the world. All Red Range shafts are created with the highest quality carbon fiber to offer low-torque performance relative to weight and stiffness.

The new range includes six shaft series (14-19), each of which is available in two models (Hi or Lo). The new naming system prioritizes dynamic performance over the non-standardized and often inaccurate static measurements that are typically used to define shaft models.

Continuous Fiber: No Seams, No Spine, No Nonsense

All Red Range shafts are created with Continuous Fiber, TPT’s patent-pending automated shaft manufacturing process that continuously winds its carbon-fiber prepreg from tip to handle around the shaft to unlock a new level of performance and consistency.

With Continuous FIber, TPT can produce golf shafts without seams or a spine, both of which are present in all conventional carbon fiber shafts and reduce performance and consistency.

“Continuous Fiber means that our shafts are made with one start and one stop,” says TPT Co-Founder Gerard Gautier. “We don’t have over-layers. We don’t have gaps. And we can do this because unlike our competitors, we’re not making shafts by hand. We’re using automation.”

Thin-Ply 2.0: Stronger, Tougher, Tighter

All TPT Red Range shafts use the company’s new Thin-Ply 2.0 carbon-fiber prepreg, which is 2X stronger and 3X tougher than the company’s original Thin-Ply material used in its Blue Range shafts.

Thin-Ply 2.0 leverages an improved resin formulation TPT developed exclusively for its golf division that gave its designers the freedom to push the performance and durability of TPT shafts even further.

Thin-Ply 2.0 is created with an automated process that takes TPT’s ultra-thin carbon-fiber prepreg and stacks it together in precise orientations. The sheets are then fused together to multiply their strength and toughness before they’re cut into strips and wound from tip to handle to create a seamless, spineless golf shaft.

Accurate Fiber Placement: A New Level of Performance

Because TPT is using automation for every step in its manufacturing process, it can accurately position its fiber from tip to handle and around all 360 degrees of a shaft. This Accurate Fiber Placement is what allows TPT to produce a wide range of distinct and fully optimized shaft models.

TPT Authorized Fitters

TPT Red Range shafts are available exclusively through a network of more than 200 Authorized Fitters located across the world. Golfers can locate an Authorized Fitter near them at tptgolf.com/get-fit.

About TPT

TPT is the golf division of North Thin Ply Technology (NTPT), a Switzerland-based technology and composites company with a track record of delivering innovative solutions for high-performance industries.

The company’s portfolio of advancements includes developing a process for producing America’s Cup yacht sails, as well as lightweight bodywork of F1 race cars, skis, and snowboards. It has also created the materials technology found in satellites and Richard Mille luxury composite watches. The record-breaking, solar-powered aircraft “Solar Impulse” also relied on NTPT-produced materials for its epic journey.

For more information on TPT Golf™, visit tptgolf.com.